We’ve talked a bit on The Academic Wino about the use of winery wastes for various purposes in order for wineries to become more sustainable. From using the wastes as therapies for various health problems (i.e. cardiovascular issues, diabetes, etc) to using

![Photo By Adrian J. Hunter (Own work) [CC BY-SA 3.0 (http://creativecommons.org/licenses/by-sa/3.0) or GFDL (http://www.gnu.org/copyleft/fdl.html)], via Wikimedia Commons](http://www.academicwino.com/wp-content/uploads/2015/09/winery-waste-3-the-academic-wino-300x235.jpg)

Photo By Adrian J. Hunter (Own work) [CC BY-SA 3.0 (http://creativecommons.org/licenses/by-sa/3.0) or GFDL (http://www.gnu.org/copyleft/fdl.html)], via Wikimedia Commons

One way wineries can be more sustainable is to adopt more environmentally-sound practices prior to arriving at the finished product. There are several programs out there for both vineyard and winery sustainability measures, many of which have started in California (ex. The Lodi Winegrape Commissions’ Integrated Pest Management system) and are now being adopted and tested in both established and more importantly developing wine regions around the globe.

One reason to try and adopt more sustainable practices before getting to the finished product is due to global wine surpluses during the past several years. According to a 2014 report by the Organisation International de la Vigne et du Vin (OIV), the global wine industry is seeing a surplus of around 30 million hectoliters, a trend which has gone on for multiple years. While there are currently incentives and programs in Europe to try and reduce these surpluses, they are not established in other countries and regions, particularly those in younger regions who are starting to churn out significantly more wine than they can sell.

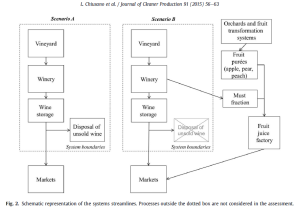

Instead of having to deal with tens of millions of hectoliters of surplus wine (which is basically considered “waste” once it can’t be sold), the authors of a study recently published in the Journal of Cleaner Production proposed a more integrative approach with other industries to try and use up as much of the unfinished product as possible before getting to the point where there is so much unsold finished wine.

Specifically, this study aimed to utilize a concept called “industrial ecology” to reduce global wine surpluses. In a more traditional system, in really rough terms, you basically start with a bunch of stuff, do a bunch of things to it, and end up with the finished product. In an industrial ecology approach, the system becomes much more integrated between different industries. Again, speaking really roughly, you start with a bunch of stuff, but share the stuff with other industries who also could utilize the same stuff at certain points in their production process. This way, the materials used to create the finished products are more efficiently utilized so that less waste is generated and thus works out to be more sustainable for all industries involved.

In this study, the researchers took an Italian winery as their subject and aimed to evaluate the environmental impact of the traditional method of making wine (i.e. start with stuff—do stuff to it—end up with wine) and compared that to a more industrial ecological approach where the grapes were utilized not only in the making of wine, but also passed along to juice makers to aid in their production processes and ultimately reduce the volume of the finished wine at the end of the process.

Brief Methods

In order to measure the environmental impact of the two scenarios briefly described in the previous paragraph, the researchers used Life Cycle Assessments, a common analytical system for measuring and analyzing environmental impact of any system. Life Cycle

Assessment (LCA) is a tool that is used to determine the environment impact associated with a particular product “from cradle to grave”. In other words, using complex mathematically modeling, LCA takes into consideration the positive and negative energy inputs and outputs from the very beginning to when an individual product is first made, all the way through when that individual product is sold to the consumer.

For the traditional approach scenario, LCA’s were performed from grape production through storage in steel tanks. For the alternative industrial ecology scenario, LCA’s were performed to include the same steps as the traditional approach, plus the transfer of must/juice to a juice production company. The LCA of the fruit juice production process was not considered as it was beyond the scope of the study. The purpose was to compare the environmental impact for just the winery itself, and not the combination of winery and juice company, though it can be predicted that overall environmental impacts would be reduced for both companies than if raw materials were utilized and processed independently as they are in traditional methods.

The unit of measure in this LCA analysis was 1 liter of wine. Basically, this means they are calculating the environmental impact it takes to produce 1 liter of wine in both scenarios.

The following procedures were included in the LCA analysis:

Vineyard: vine establishment, nursery stage, production stage of the young vineyard, production stage of the mature vineyard, production stage of an aged vineyard, and disposal of vineyard systems and equipment.

Winery: energy consumption, water consumption, wine additives, gases used, and packaging materials (including glass, closures, labels, capsules, paper boxes, and bag-in-box). Specific stages of wine production evaluated were: wine unloading, blending, fining, racking, filtration, cold stabilization, storage in tanks, microfiltration prior to bottling, and unpacking of unsold wines.

LCA analysis took place for the 2012 and 2013 vintages for Barbera wines made at a winery located in Priocca, Italy.

Selected Results

- The traditional approach had a greater environmental impact than the industrial ecological approach.

- The industrial ecological approach reduced global warming potential (i.e. carbon footprint) and nutrient enrichment potential by 4%, and by 2% for acidification potential.

- Total CO2 emissions for the traditional approach was 0.896kg CO2 per 1 liter of wine, while total CO2 emissions for the industrial ecological approach was 0.861kg CO2 per 1 liter of wine.

- For this particular winery, using the industrial ecological approach translated to a 18.9 ton reduction in their carbon footprint over the total volume of wine produced (even though it doesn’t look like a big difference when you look at it at the single unit level).

- The vineyard side of production had a greater environmental impact than the winery side of production.

Conclusions

The results of the Life Cycle Assessment of two different scenarios: the traditional system of making wine versus a system where materials are shared between different industries, indicated that utilizing this shared approach may be more sustainable overall by reducing the carbon footprint produced by a single winery and reducing the amount of wine produced and ultimately helping to reduce the global wine surplus issues that we have seen in recent years.

It is important to note that since the wine industry is highly variable, be it through different climate impacts, and countless differences in vineyard and winery management practices from winery to winery, these results likely can’t be global generalized for every single vineyard and winery out there. However, it does show that there is potential for this more

integrated approach of sharing materials with other industries could be beneficial from an environmental perspective, and shows that for at least some wineries it could be an effective way to help reduce their output so they end up with fewer unsold wines.

It would be very interesting to see a more birds-eye view approach to this system by performing LCA analyses on the entire system including the production of juice from these shared materials and comparing that to a more isolated/traditional juice making approach. In other words, take the same study presented today, but simply add the juice production layer and compare. I would guesstimate that we would see an overall reduction in the carbon footprint for BOTH wine and juice industries, as sharing raw materials simply means that the individual companies are using less to begin with, thus putting in less energy and materials to produce their final products.

Overall, I think that a shared approach to utilizing raw materials across industries is a viable solution to improving industry sustainability and reducing overall surpluses and waste. Since individual wineries can be so variable in terms of their production methodologies, having a multitude of options to help reduce their carbon footprints and improve sustainability is critical if we want the entire industry to do their part. However, adopting an industrial ecological/integrated approach definitely sounds like it could be an effective player in the arsenal of programs that wineries and vineyards can adopt to improve global wine industry climate impacts and at the same time reduce wine surpluses in the marketplace.

Source: