Malolactic fermentation is a common process that occurs after primary alcoholic fermentation is complete. Occurring in most red wines and some white wines (including Chardonnay and sparkling wines), it functions to reduce the acidity of the wine by converting L-malic acid to L-lactic acid with a carbon dioxide by-product. Malolactic fermentation ultimately increases the complexity of the finished wine, as well as provides microbial stability.

If malolactic fermentation does not come to completion, lactic acid bacteria can remain in the wine and cause several problems, including the production of unwanted volatile compounds that introduce undesirable flavors and aromas to the wine (including, but not limited to, mousiness and bitterness) as well as the production of biogenic amines that can be harmful to human health when ingested.

As a result of these negative implications of lactic acid bacteria remaining in wine, it is of utmost importance that the progress of malolactic fermentation be monitored and determined when it has been completed. Current methods of monitoring malolactic fermentation include paper chromatography, thin layer

![Traditional paper chromatography for monitoring malolactic fermentation progress.By Agne27 (Own work) [CC-BY-SA-3.0 (http://creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons](http://www.academicwino.com/wp-content/uploads/2013/01/malolactic-fermentation-paper-chromatography-The-Academic-Wino-224x300.jpg)

Traditional paper chromatography for monitoring malolactic fermentation progress.

By Agne27 (Own work) [CC-BY-SA-3.0 (http://creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons

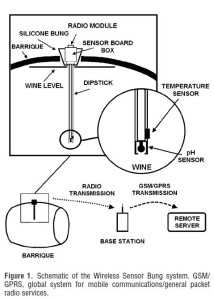

A novel method for monitoring malolactic fermentation in wine is presented today in this article and is tested by the authors of the study for its effectiveness and accuracy in determining the progress and completion of malolactic fermentation. Specifically, a wireless real-time system dubbed the “Wireless Sensor Bung” system is presented to show that it can function to remotely monitor the parameters in wine and to determine if malolactic fermentation has been completed in a more cost-effective and timely manner.

Methods

Wireless Sensor Bung

See Figure 1 for a illustration of the Wireless Sensor Bung

The Wireless Sensor Bung consists of a sensor node that is kept in the silicone bung of a wine barrel as well as a receiving base station. The sensor node is made up of a sensor probe with both analog and digital channels in order to connect various sensors for data collection, as well as a radio for wireless data transfer. Other sensors on the node measure both temperature and pH.

The base station for the Wireless Sensor Bung is set up with a coordinator device that serves to “talk” between the sensor node and the computer program that is collecting the data received by the node. In order to achieve this communication, the base station is equip with a USB connection for back-and-forth between the station and the computer.

A unique software management program is installed on the laboratory computer in order to receive and analyze the data transmitted through the sensor node and the base station. Data can be both stored and also measured in real-time.

Functionally, the sensor probe measures the wine parameters, then the data is sent via radio signal to the base station. The data is then transferred to a remote server and the data then analyzed using the computer software management program.

Testing the Wireless Sensor Bung

The Wireless Sensor Bung was tested in 2011 at the Azienda Agricola Comparini winery in Empoli, Tuscany, Italy. The base station was placed behind a cellar wall in order to determine if there may be issues with interference due to the architecture of the cellar.

The sensor node was placed into a 225L Bordeaux-style barrique/barrel of Sangiovese red wine. To determine reliability and accuracy, the sensor was set to acquire data every 5 seconds. The authors stressed it is not necessary in real world situations to have data collect this frequently, but was chosen in this case for testing the reliability and accuracy of the system.

To determine the accuracy of the data being collected by the Wireless Sensor Bung, wine was also sampled from the barrels and tested using traditional chromatography methods. For each wine sample, the following were analyzed: lactic acid bacteria population, L-malic acid, L-lactic acid, and pH.

Results

- During the calibration process, the Wireless Sensor Bung showed high precision and response stability of the sensor node.

- By setting the data acquisition time at 5 seconds, the device lasted 8 days before the battery dropped to a level that interrupted data collection.

- A total of 17,280 observations per day were collected at this rate (wine temperature and pH) and were subsequently averaged for a daily value.

- In “normal” situations (i.e. in the real world at the winery), the authors stressed only 4 values per day need be collected. This would allow up to 75 days of data collection on one battery charge.

- Data collected using the Wireless Sensor Bung and the traditional chromatography methods were very similar.

- The only difference was that the correlation between pH and malic acid concentration was higher using the Wireless Sensor Bung than using the traditional method.

- This indicates the Wireless Sensor Bung could be superior to traditional methods.

- The only difference was that the correlation between pH and malic acid concentration was higher using the Wireless Sensor Bung than using the traditional method.

Conclusions

This study examined a novel method for analyzing the progress and completion of malolactic fermentation in an Italian red wine, and showed that using a wireless real time monitoring system (i.e. the Wireless Sensor Bung) may be a good, if not superior, alternative to the traditional monitoring systems, in that the data collected are accurate and show great stability in terms of data collection and power supply.

The authors indicated that this Wireless Sensor Bung system could be

![By Tomascastelazo (Own work) [CC-BY-SA-3.0 (http://creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons](http://www.academicwino.com/wp-content/uploads/2013/01/wine-barrel-The-Academic-Wino-300x212.jpg)

By Tomascastelazo (Own work) [CC-BY-SA-3.0 (http://creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons

This system should be tested using other wines to ensure the results are consistent regardless of the type of wine being crafted. If it proves to be consistent from wine to wine and from winery to winery, the Wireless Sensor Bung could be a good investment in terms of both time and financial resources for the individual players in the wine industry.

Source: Di Gennaro, S.F., Matese, A., Primicerio, J., Genesio, L., Sabatini, F., Di Blasi, S., and Vaccari, F.P. 2012. Wireless real-time monitoring of malolactic fermentation in wine barrels: the Wireless Sensor Bung system. Australian Journal of Grape and Wine Research. doi: 10.1111/ajgw.12006