In response to climate change, it is the responsibility of every business and industry to take a step back and evaluate their own environmental impacts in order to find places where they might be able to cut back or change in order to be more environmentally friendly and maybe even sustainable. What’s known as Life Cycle Assessments (LCA), evaluating the “cradle to grave” for one unit of product is an effective way to determine a business or industry’s impact on the environment.

Here on The Academic Wino, we’ve covered LCAs of various aspects of the wine industry, including the environmental impact of producing a single bottle of wine in Nova Scotia as well as a two part piece highlighting the environmental impact of the wine distribution chain in the United States (Part I and Part II).

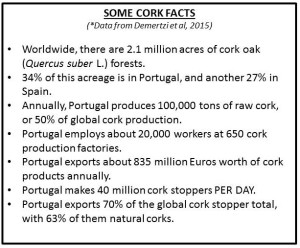

One important part of the life cycle of a bottle of wine that was not part of the LCA studies covered on this blog is related to the closure. Natural cork stoppers are the historical fan favorite for closing bottles of wine, and though while nowadays there are many more options, natural cork still remains a popular choice for many wineries.

How to Make a Cork Stopper 101:

Grown and cultivated from cork oak (Quercus suber L) forests, cork stoppers have to go through four distinct stages before it is takes on the form and function of the beloved closure.

- The first stage in becoming a cork stopper is the forest management stage. Here, environmental impacts can be made in:

- The establishment of the cork oak forest stand;

- Maintaining the stand;

- Stripping the cork;

- And harvesting the entire tree at the end of its 170 year life to make room for new trees.

- Getting the forest workers to and from the cork oak stand can also be an important part of the forest management stage.

- The second stage is the cork preparation stage. Five things typically occur during this stage:

- The piling up of the cork planks;

- A 6-month stabilization period;

- The boiling of the planks;

- A 3-week stabilization period;

- And scalding or second boiling.

Cork planks also need to be manually inspected for structural issues, and if rejected by the worker, it gets sent to other manufacturing facilities to make agglomerated cork products.

- The third stage is cork stopper production stage. 11 things typically occur during this stage:

- Slicing;

- Punching;

- Pre-drying;

- Corrections;

- Removal of dust;

- Selection (manual and automatic);

- Washing;

- Drying;

- Deodorizing/Cleaning;

- Coloring;

- And Packaging.

In some cases, a final transportation step from the production facility to the manufacturing facility is needed.

- The fourth stage is the finishing stage. 6 things typically happen during the finishing of natural cork stoppers:

- Removing dust;

- Branding;

- Printing;

- Surface treatment;

- And Packaging.

In some cases, a final transportation step from the manufacturing facility to the finishing facility is needed.

Which of these stages are most influential in terms of their impact on the environment? Are there ways to reduce the environmental impact of producing natural cork stoppers based on their current Life Cycle Assessment?

New Research – Unit of Measure and Methods

A new study accepted into the Journal of Cleaner Production looked at these very questions and presents a thorough analysis of the Life Cycle Assessment of natural cork as well as suggestions on how to potentially reduce the environmental impact of natural cork production.

With any Life Cycle Assessment, you need to know your basic unit (i.e. a single bottle of wine, a case of

wine, a single cork, a bunch of corks, etc). In this case, the researchers chose the unit to be the production and delivery of 1000 natural cork stoppers from CorkSupply Portugal SA.

Production and manufacturing data were provided by CorkSupply Portugal SA and was assumed to be typical for natural cork producers in Portugal and elsewhere. Emissions data were collected from the IPCC (Intergovernmental Panel on Climate Change) and EMEP/EEA (European Monitoring and Evaluation Programme/European Environment Agency).

The Life Cycle Assessment was applied to the four stages of natural cork production described above, in addition to the transport of both workers and distribution of corks to end points in Europe and the United States.

For this particular study, the distance between the cork forest and the preparation facility was 58km, the distance between the preparation facility and the manufacturing facility was 308km, and the distance between the manufacturing facility and the finishing facility was 6km.

For the distribution arm of the Life Cycle Assessment, truck and ship use were analyzed (truck for local shipments and ship for overseas shipments).

Electricity, chemicals, fuel, and vehicle emissions data were collected from the Ecoinvent database.

Environmental impact measures for each stage of the natural cork stopper Life Cycle Assessment included:

- Climate change (kg CO2 eq)

- Ozone depletion

- Human toxicity cancer effects

- Human toxicity non-cancer effects

- Photochemical ozone formation

- Acidification

- Terrestrial eutrophication

- Freshwater eutrophication

- Marine eutrophication

- Freshwater ecotoxicity

- Mineral and fossil resource depletion

Results

- The forest management stage had the biggest environmental impact overall compared with the other four stages of the natural cork production/manufacturing process.

- Specific categories of greatest impact were: ozone depletion, photochemical ozone formation, acidification, terrestrial eutrophication, marine eutrophication, and mineral & fossil resource depletion.

- Most of the environmental impacts in this stage came from the machinery and equipment used to carry out cork forest management tasks, specifically the cork stripping process (76%-99% of the total environmental impact of this stage).

- The cork preparation stage had the greatest impact on the categories of human toxic non-cancer effects and freshwater ecotoxicity.

- Most of the environmental impacts related to human toxic non-cancer effects and freshwater ecotoxicity came from zinc and copper leachate from sludge/cork waste and wastewater.

- For all categories, the boiling step had the greatest environmental impact due to the use of electricity (59%-79% of the total impact of this stage).

-

For the climate change (CO2) and ozone depletion categories, the burning of natural gas and production of consumed heat were the biggest culprits in this stage.

- The cork stopper production stage had the greatest impact on the categories of climate change (CO2) and human toxic cancer effects.

- Most of the environmental impacts in this stage came from natural gas use and the chemicals used to wash the cork stoppers, though transporting the planks from the preparation facility to the manufacturing facility also played a role.

- The washing of the cork stoppers impacted four different categories, namely human toxic cancer effects, human non-toxic cancer effects, freshwater ecotoxicity, and mineral & fossil resource depletion (30%-66% of the total impact of this stage).

- Transporting the corks 308km from the preparation facility to the manufacturing facility impacted the categories of photochemical ozone formation, marine eutrophication, and terrestrial eutrophication, mostly due to the emissions made from using diesel in the trucks.

- The deodorizing step impacted the categories of climate change (CO2) and ozone depletion, mostly from the burning of natural gas.

- The punching step impacted the categories of acidification and freshwater eutrophication, mostly due to the electricity used by the equipment needed for this step.

- The finishing stage had the greatest impact on the freshwater eutrophication

- Most of the environmental impacts in this stage came from phosphate emissions generated from the electricity used.

- For all categories, the surface treatment step had the greatest environmental impact primarily due to use of electricity, though the use of paraffin and silicon during this step also likely played a role.

- The dusting and branding steps were similar in their environmental impact as the surface treatment step, though not quite as much.

- The distribution stage influenced most categories as a result of the ship transport to the US where the distance traveled and diesel consumed were much greater than closer truck shipments.

- The categories of human toxic non-cancer effects and freshwater eutrophication were actually higher in the distribution to France.

Alternative Scenarios

- Alternative scenarios for all four stages were evaluated and it was determined that the only scenarios were there were significant (i.e. greater than 5%) improvement in the environmental impact of natural cork production came from the forest management stage.

- “Winning” scenario (during the forest management stage):

- Do not perform routine pruning when going in to perform cork stripping.

- Use rotary mowers instead of the more traditionally-used disc harrowers for cleaning.

- Adopting these changes could result in a 3-65% decreased environmental impact.

Conclusions

The results of this study provide a detailed description of the Life Cycle Assessment of producing 1000 natural corks from forest management to distribution.

One thing not included as a part of the Life Cycle Assessment of the natural cork was what happens to the cork after it has been popped from the bottle of wine and is either thrown away or recycled for other uses. I would guess the environmental impacts would be very low compared to the other stages of the process, but I would need some research to confirm or refute my thoughts.

According to the results of this study the greatest environmental impact of producing natural corks came from the forest management stage, with this stage also the stage where the best alternatives to reducing the overall environmental impact can be had.

One thing I thought was surprising was the finding that the alternative scenario having the preparation, manufacturing, and finishing facilities all in the same location (or close enough where diesel consumption and emissions are negligible) did not have a significant impact on the Life Cycle Assessment of producing natural cork stoppers. In this example, they had to truck around the cork products from place to place throughout the process, though apparently not enough warrant moving the facilities closer together.

One final question that came to my mind after reading this study was: How does the Life Cycle Assessment of producing 1000 natural corks compare to the Life Cycle Assessment of producing 1000 other types of closures? Is it better? Worse? Comparable? I would like to see an independent study (NOT paid for by a closure company or anyone else with conflicts of interest) comparing the Life Cycle Assessments of all the different closure types.

Overall, I thought this was a very interesting and informative study, but then again, I’m always a fan of Life Cycle Assessment studies. This work should provide some guidance for those in the natural cork industry in hopes that they may take a step back and reevaluate their own production methods and move toward implementing new practices and techniques for doing their part in improving environmental impact.

Please feel free to leave a comment if you have any questions regarding the study findings, tested alternative scenarios, or anything else related to the topic!

Source:

6 comments for “The Environmental Impact of Producing Natural Cork Closures”