With an ever increasing number of mouths to feed word wide and a food supply that has seemingly gone downhill in terms of its quality, the interest in developing and producing functional foods – or foods that are enriched in various health beneficial nutrients – is ever

![Photo By Adrian J. Hunter (Own work) [CC BY-SA 3.0 (http://creativecommons.org/licenses/by-sa/3.0) or GFDL (http://www.gnu.org/copyleft/fdl.html)], via Wikimedia Commons](http://www.academicwino.com/wp-content/uploads/2015/08/winery-waste-the-academic-wino-300x216.jpg)

Photo By Adrian J. Hunter (Own work) [CC BY-SA 3.0 (http://creativecommons.org/licenses/by-sa/3.0) or GFDL (http://www.gnu.org/copyleft/fdl.html)], via Wikimedia Commons

At the same time, it is important to pursue new technological advances in the spirit of sustainability, as many food and agricultural practices are not sustainable and at times have detrimental effects on the environment (if not immediately then certainly long term). To that end, utilizing specific agricultural wastes – like winery wastes – may be an option to not only produce nutritional functional foods or products and to reduce the overall waste to the environment and reduce the carbon footprint of the industry.

Winery wastes have been looked at for many different applications – the rich polyphenols and other health-benefitting compounds in the skin/seed wastes left over from winemaking have been shown to be beneficial for numerous reasons. To name a few examples, winery wastes have been shown to be possible alternative fuel sources, while also acting as meat preservatives, an additive to improve the quality of finished wines, and an analgesic to a whole host of health problems (including diabetes, cardiovascular problems, and influenza).

One question that arises is what is the best way to process these winery wastes to make them useable for various applications? Of course, there may not be a single appropriate answer here, since you’re dealing with applications as diverse as using winery wastes as fuel to using them as nutrient supplements for various ailments. For example, in past studies, winery wastes have been processed into liquid extracts and either applied in that phase or condensed and process further into pill form.

A new study presented today in the journal Food Chemistry aimed to test a new way of processing winery wastes for applications like functional foods or nutraceuticals, since it is known that polyphenols have a relatively short shelf. Specifically, this new study examined the feasibility of processing winery wastes via microencapsulation into little microbeads. This microencapsulation technique has been used in the pharmaceutical industry and is known to improve the shelf life of various medicines, but its ability to improve the shelf life of polyphenols in winery wastes is unknown.

It is important to note this study does not do a comparison to all other current forms of processing, but instead is a proof of concept study as well as a preliminary study on the efficacy of these microbeads in maintaining polyphenol stability and bioavailability over time.

Brief Methods

(If you need more details, please let me know and I’ll try to pull together some answers for you).

To make the microencapsulated beads (i.e. calcium alginate beads), brown algae, chitosan, (+)-catechin standards, and (-)-catechin standards were used.

Winery wastes were obtained from wineries in the Rioja and Txakoli regions of Basque Country, Spain. The wastes were composed of Tempranillo and Hondarribi zuri grapes. Wastes were dried, mixed, and then developed into an extract.

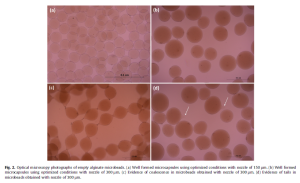

Microbeads were produced using the vibrating nozzle method. Beads of two different sizes were produced and analyzed: 150μM and 300μM. The microbeads were created and hardened using sodium alginate, winery waste extracts, and calcium chloride.

Polyphenols were analyzed using HPLC-DAD (high performance liquid chromatography).

Long-term stability of polyphenols in the microbeads were tested and analyzed for 6 months under different conditions: at -4oC in the dark, room temperature in the dark, and room temperature in the light.

(+)-catechin and (-)-catechin content of the microbeads were analyzed over 185 days.

As a control, long-term stability of polyphenols in “free” winery wastes were also analyzed under the same conditions as the microbeads.

Selected Results

(Again, if there are specific results you’re curious about that I did not mention, just ask and I’ll check to see if the researchers covered it).

- The amount of polyphenols released and lost during the hardening process was reduced when the larger nozzle size was used (300μM).

- There appeared to be no polyphenols lost when winery wastes were freeze dried prior to processing and the 300μM nozzle/bead size was used.

- Freeze-dried beads possessed a fine granulated character, while drying at a constant warmer temperature resulted in beads sticking together.

- The former would be better for food-grade usage, as it would not create a “lumpy” feel in the mouth.

- Microbeads created with the smaller sized nozzle (150uM) had polyphenols with half-lives of between :

- 619 and 857 days when kept in the dark at -4oC,

- 72 and 89 days when kept in the light at room temperature,

- 139 and 152 days when kept in the dark at room temperature.

- When chitosan was added, degradation of polyphenols decreased by 3-7%.

- Microbeads created with the larger sized nozzle (300uM) had polyphenols with half-lives of between :

- 465 and 510 days when kept in the dark at -4oC,

- 361 and 478 days when kept in the light at room temperature,

- 157 and 163 days when kept in the dark at room temperature.

- When chitosan was added, degradation of polyphenols decreased by 1-16%.

- Slower degradation rates for (+)-catechin and (-)-catechin were noted at the lower temperatures.

- The addition of chitosan improved the stability of the microbeads.

- 16-22% less degradation was seen in the 150μM-sized microbeads when stored in the darkness.

- 17-31% less degradation was seen in the 300μM-sized microbeads when stored in the light.

- The 300μM microbeads were less sensitive to degradation at room temperature compared with the smaller beads.

- The “free” winery wastes degraded significantly more and faster than microencapsulated winery wastes.

- Microencapsulation of winery wastes improved the half-lives of polyphenols by 5 to 33 times what they would be if left in a free state.

![Photo By davitydave (Flickr: P1010415.JPG) [CC BY 2.0 (http://creativecommons.org/licenses/by/2.0)], via Wikimedia Commons](http://www.academicwino.com/wp-content/uploads/2015/08/winery-waste-2-the-academic-wino-300x225.jpg)

Photo By davitydave (Flickr: P1010415.JPG) [CC BY 2.0 (http://creativecommons.org/licenses/by/2.0)], via Wikimedia Commons

In what is mostly a proof-of-concept study, the results show that processing winery wastes into microencapsulated beads significantly improves the shelf life of the polyphenols contained therein by between 72 and 857 days, depending upon the size of the beads and the temperature at which they are stored. The larger 300uM beads appeared to be less sensitive to degradation and have a longer shelf-life, though texturally may be inferior to the smaller, finer 150uM microbeads. A sensory analysis would be beneficial to determining if this size difference actually matters in terms of gustatory satisfaction.

More research is, of course, needed in order to further optimize the development of the microencapsulation of winery wastes, including using different types of winery wastes (i.e. different grapes), but it does appear from the results of this study that it may very well be a viable option to help preserve polyphenol integrity and shelf-life for use in various food or pharmaceutical and nutraceutical applications.

Source: